Resource created by RED research and design

Industrialization - second part

The tools you didn't expect

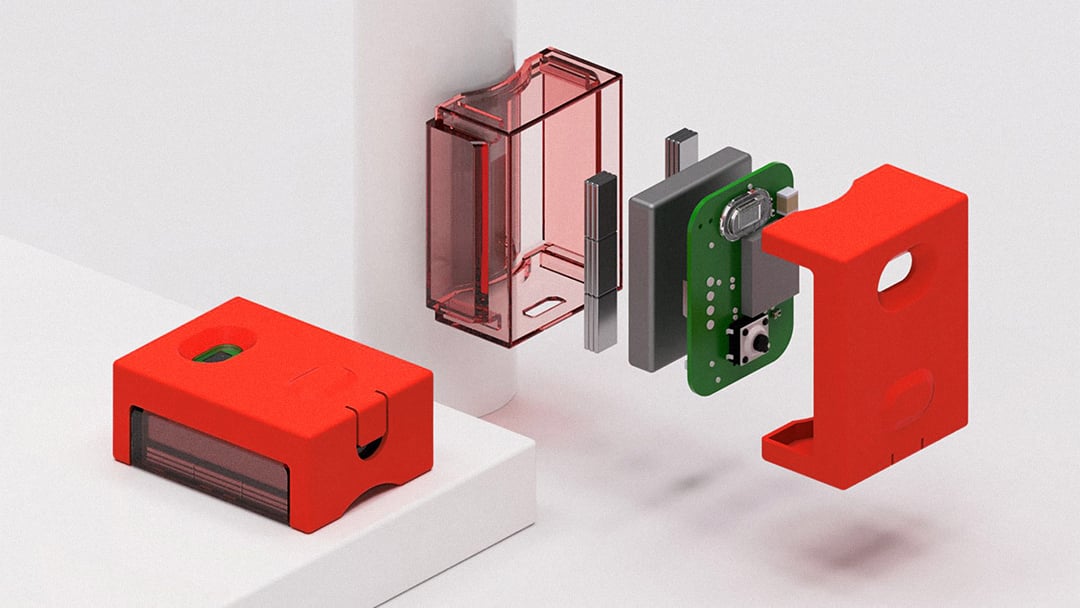

We mentioned it in the last part of this resource: in production it is often necessary to arrive ready not only with the project of our device, but also a series of "accessories" preparatory to the manual/automated actions that will have to be carried out. Sometimes, these accessories are in charge of the manufacturing company, realized autonomously, other times a direct comparison with the designer is necessary. For the world of electronics, a typical example is that of the touch probe, bed of nails or also called fixture machine. This is a system, ideally represented as a "toaster", in which on one side there is a panel for placing your electronic board and on the other side there are contrast pins. When you close the two sides, with your board in between, the contrast pins hold the board in place and needles underneath contact specific points on your circuit, i.e. test-points. These points will typically be the power supply, programming access and debugging of your system. The needles are then electronically connected to a system you design, which will allow programming and testing of your boards.

Imagine a line operator having to shut down the fixture hundreds of times, simply push a button, allow the machine to program multiple boards simultaneously, and view the test log. There, the word "simply" is the one that rubs. Anything that needs to be "simple" downstream is usually complex upstream and time consuming to develop. The design of a fixture is almost a product in itself, in which are included:

- mechanical skills, some of which can be managed with an outside fixture supplier;

- electronic skills, often are used commercial boards of fast and easy use (e.g. raspberry, pc, etc.)

- software and firmware skills. The above mentioned "button", triggers a series of tasks that can be for example: contact one of your server, download a FW test release, prepare a log of the test results, upload the log on another part of the server, interface a label printer that will print the serial of the board or an error code of the test, flash the final FW on the board.

This is just an example of a process, depending on the product, there are dozens of possible flows. Obviously the more steps there are, the more the probability of problems increases.

Lead Time not to be underestimated

To make a simple double-cheeked mold without inserts, for a device with a complexity comparable to your mouse, here, consider at least 5-7 weeks of work by your supplier. To make the mechanics of a fixture externally, instead, consider at least 3-4 weeks.

To make an electronic pre-series (e.g. 100 pieces) from the moment you deliver all the executive files, consider at least 4-5 weeks. There are many other examples, but consider that these are average times. There are situations where the time can be reduced by half or, in the worst case, increased. The factors that influence these times are really many: from the complexity, the finding of the raw material, the quantities, to how much you are willing to spend.

Not to mention if the above mentioned processes are carried out in Asia. If the goods are compact and costs allow, air shipping can be contemplated. Otherwise, be prepared to add more weeks of waiting between shipping and customs. Customs unfortunately is a sometimes unpredictable part of your supply chain. You could devote an entire article to it, complete with quotes and real-life examples. The bottom line is that it should not be overlooked and it is good practice to have a contingency on your planning when ordering goods outside the EU.

Even a label matters

You arrive in production. In fact, just before starting, you decide to devote yourself to the last piece of work procrastinated until now: the product label. Without realizing it, you are opening Pandora's box. A "simple" label hides behind itself:

- type of label (thermal, self-adhesive, format, ...) and its printer to be used (average cost 300-400€)

- a software interface that, for example, is able to receive data from a barcode reader, interact with the firmware of your product, log data on a server, etc. etc

- a hardware able to host the above mentioned software

- the content to be written on the label (product code, certifications, symbol raee, etc)

The list could be very long, and there can be more than one label at different stages of the manufacturing and assembly process. So, you can imagine how the level of complexity can increase considerably in the blink of an eye, having then to involve different professional figures from the software developer, to the logistics manager, passing through proprietary or third-party managed cloud services, etc. Times are getting longer and the marketing/commercial sector is pressing.

In short, we are talking about a complex task, which should not be underestimated.

Returns: the sword of Damocles

Another aspect of which we do not realize the complexity, until it happens, is the management of returns

A customer who buys a product online, according to EU regulations, has the right of withdrawal within 14 days from the date of delivery. This is the minimum, then there are all the variations of the case. Either way, this means that your product can be purchased, used, repackaged and returned to the factory.

If the product is returned, it must follow a specific path that must be properly outlined. As with the label, this will involve several colleagues, because you will need to create a computerized path that can update your server/management.

Returns must then be tested one by one, especially if the cause of the return is related to a malfunction or production defect. Then the factory must be able to interface with customer care, which will have the traceability of communications with the customer

Once all the necessary tests have been carried out and based on the outcome, the product must be "re-introduced" into the line by updating the data on the management system and possibly considering the use of other components from the warehouse in case of replacements/repairs. Therefore, there must be an interaction with the components warehouse that must be constantly updated.

Logistics and keeping track

First with labels and then with returns, we mentioned logistics. This is literally a parallel world that you need to know carefully and that you rely on external logistics services.

Focusing only on internal project activities, we distinguish mainly two types of activities: management of inbound (incoming goods) and outbound (outgoing goods).

The first refers to the so-called "supply chain manager". That is, the person who, from the warehouse to the R&D department, must keep track of the components to be purchased, lead times, negotiations on quotes, surpluses, control of incoming goods, etc. Depending on the complexity of the system, there may obviously be multiple people covering supply chain activities.

Important thing: mark all Chinese holidays! From New Year's Eve, which for them lasts at least 2 weeks, to other festivities scattered throughout the year. Each holiday event can cause a block in deliveries of at least a week.

While for outbound management, the main internal interactions are with marketing, sales, customer care and production manager. For outbound, on the other hand, it is necessary to know how to manage more than one courier, especially if you work with foreign countries. It's important to know how to use the platforms that forwarders make available, and to find a way to connect your management system with theirs. Again, this opens another Pandora's box that will involve your (overloaded) software developer or IT department (it always depends on the size of the project/company).

Finally, always considering the situation of the small business reality/startup, it is necessary to lend oneself to more manual and time-consuming activities (even days) for the printing of transport documents, the packing with the correct order of disposition of all the sheets, the different shipping labels, the subdivision by couriers and/or country of destination, the organization of the different pickups of the packages with the relative time slots made available by the courier, etc. All activities, as always, not to be underestimated and kept in mind.

Marketing and unexpected orders

If you are in a launch phase, it may happen to receive requests from your sales/marketing colleagues about the availability of extra shipments to preferred contacts or customers. The reasons can be many, from a trade show abroad to a photo shoot for an advertising campaign, etc. Flexibility and responsiveness at this juncture is important. To be so, you need to have a dynamic system in place to record these occasional events and be able to update your inventory count.

Tip: make the numbers you master accessible and usable, for example with a simple GUI.

Our journey from concept to industrialisation ends here!

Come and visit our website to keep up to date with our projects: www.researchandesign.it